Introduction

Modern CNC machines and industrial motor-driven systems demand precise speed control, energy efficiency, and long-term reliability. One of the most critical components that enables this level of performance is a Variable Frequency Drive (VFD). The MOLLOM VFD 4KW 5HP 380V Variable Frequency Drive is designed specifically to meet these demands, offering high-frequency output, flexible input phase compatibility, and advanced digital control features suitable for CNC routers, milling machines, pumps, compressors, and many other industrial machines.

This in-depth article explores the MOLLOM VFD 4KW 5HP inverter in detail, explaining its technical specifications, real-world applications, advantages, limitations, and suitability for different users. The content is written to be clear, accurate, and useful for both beginners and experienced CNC operators. All product data is compiled based on verified Amazon product listings and manufacturer specifications, without external links or references.

What Is a Variable Frequency Drive and Why It Matters

A Variable Frequency Drive controls the speed and torque of an electric motor by adjusting the frequency and voltage of the power supplied. Unlike traditional on-off motor control, a VFD allows smooth acceleration, deceleration, and precise RPM adjustment.

Key benefits of using a VFD include:

- Improved motor lifespan

- Reduced power consumption

- Precise speed and torque control

- Lower mechanical stress on equipment

- Enhanced safety and automation capability

The MOLLOM VFD 4KW 5HP is built specifically for high-speed spindle motors and industrial loads where precision and stability are essential.

Overview of the MOLLOM VFD 4KW 5HP Inverter

The MOLLOM VFD 4KW 5HP inverter is a compact yet powerful motor controller supporting both single-phase and three-phase AC 380V input. It outputs a stable three-phase AC signal with a frequency range up to 3000 Hz, making it suitable for high-speed spindle motors commonly used in CNC machines.

This VFD stands out due to its advanced digital control interface, RS485 MODBUS communication, and strong anti-interference protection. Its versatility allows it to be used across a wide range of industrial applications beyond CNC machining.

Key Technical Specifications

The table below summarizes the core technical data of the MOLLOM VFD 4KW 5HP, compiled from Amazon product data and manufacturer descriptions.

Technical Specifications Table

| Specification | Details |

|---|---|

| Rated Power | 4KW (5HP) |

| Rated Current | 9A |

| Input Voltage | AC 380V ±15% |

| Input Frequency | 50/60 Hz |

| Input Phase | Single-phase or Three-phase |

| Output Voltage | AC 380V |

| Output Phase | Three-phase |

| Output Frequency Range | 0–3000 Hz |

| Control Mode | V/F Control |

| Communication | RS485 MODBUS |

| External Resistor Support | Yes |

| Display Type | Digital LED |

| Dimensions | 5.3 × 7.3 × 3.9 inches (135 × 185 × 100 mm) |

| Cooling Method | Forced air cooling |

| Installation Type | Wall-mounted |

Design and Build Quality

Despite its compact size, the MOLLOM VFD 4KW 5HP is built with industrial-grade materials. The enclosure is designed to dissipate heat efficiently while protecting internal components from electrical interference. The internal cooling fan ensures stable operation during prolonged use.

The terminal layout is clearly labeled, allowing for easier wiring and maintenance. The detachable control panel adds flexibility, enabling remote mounting for control cabinets or CNC control panels.

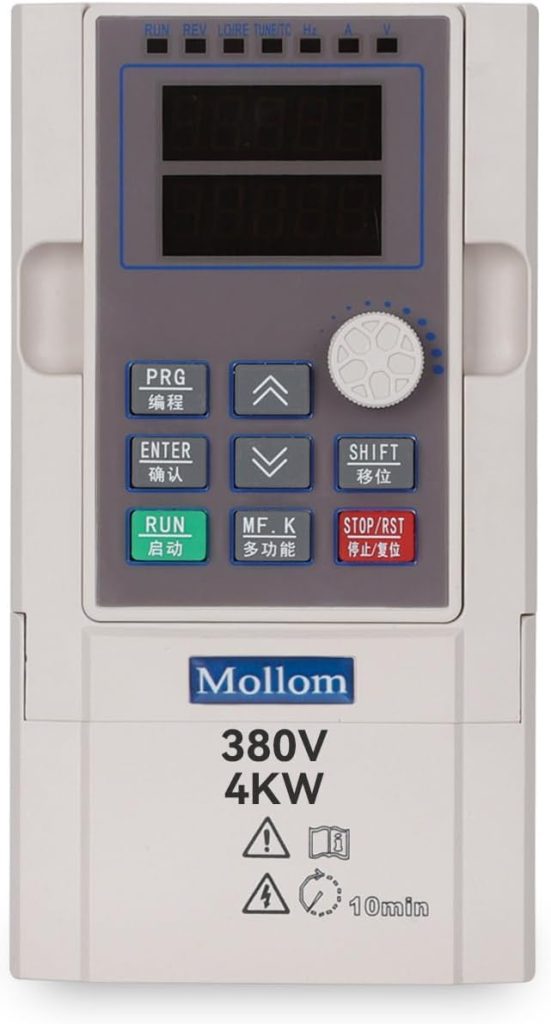

Smart Digital Display and User Interface

One of the most appreciated features of the MOLLOM VFD inverter is its user-friendly digital interface.

Key Interface Features

- Clear LED digital display

- Intuitive keypad layout

- Easy parameter programming

- Detachable control panel for remote operation

The digital display provides real-time information such as frequency, speed, and fault codes, making diagnostics and adjustments straightforward even for users with limited VFD experience.

Control Capabilities and Communication Features

The MOLLOM VFD 4KW offers both digital and analog control terminals, allowing flexible integration into different control systems.

Control Options

- Start/stop via keypad or external terminals

- Speed control via potentiometer or analog signal

- Direction control via digital input

- Programmable acceleration and deceleration

RS485 MODBUS Communication

The integrated RS485 communication port supports standard MODBUS protocol, enabling:

- Integration with CNC controllers

- Remote monitoring and control

- Automation system compatibility

This makes the VFD suitable for modern CNC setups and industrial automation environments.

High-Frequency Output for Spindle Motors

A defining feature of this VFD is its 0–3000 Hz output frequency range, which is significantly higher than standard industrial VFDs. This capability is essential for high-speed spindle motors used in CNC routers and engraving machines.

High-frequency output allows:

- Higher spindle RPM

- Improved cutting precision

- Smoother surface finishes

- Reduced vibration

This makes the MOLLOM VFD 4KW 5HP an excellent match for water-cooled and air-cooled spindle motors.

Supported Applications

According to Amazon product data and manufacturer recommendations, this VFD is suitable for a wide range of machines.

Common Applications Table

| Application Type | Compatibility |

|---|---|

| CNC Router | Excellent |

| CNC Milling Machine | Excellent |

| Drilling Machine | Excellent |

| Grinding Machine | Excellent |

| Winding Machine | Good |

| Mixer | Good |

| Extruder | Good |

| Slitter | Good |

| Conveyor System | Excellent |

| Elevator System | Good |

| Compressor | Excellent |

| Ventilator | Excellent |

| Water Pump | Excellent |

| Centrifuge | Good |

Electrical Safety and Anti-Interference Performance

The MOLLOM VFD inverter is designed with strong anti-jamming capability, ensuring stable operation in electrically noisy environments such as workshops and factories.

Safety Features

- Overvoltage protection

- Overcurrent protection

- Short-circuit protection

- Overheating protection

- Anti-electromagnetic interference design

These features protect both the VFD and the connected motor from damage due to electrical instability.

External Resistor and Braking Capability

This VFD supports the connection of an external braking resistor, which is essential for applications requiring rapid deceleration or handling high inertial loads.

Benefits of External Resistor Support

- Faster motor stopping

- Reduced DC bus voltage spikes

- Improved safety for heavy loads

For motors under heavy load, the manufacturer recommends selecting a higher power VFD or consulting for proper model selection.

Installation and Wiring Considerations

Correct installation is crucial to ensure the longevity of the MOLLOM VFD 4KW 5HP.

Important Installation Notes

- The VFD must be connected directly to the motor

- Motor start and stop must be controlled only through the VFD

- Do not use external contactors to interrupt motor power while the VFD is running

- Ensure proper grounding

- Maintain adequate ventilation

Failure to follow these guidelines may result in permanent damage to the inverter.

Environmental Requirements and Limitations

The working environment plays a significant role in VFD performance.

Environmental Warnings

- Avoid humid environments with water mist or droplets

- Prevent metal objects from falling into the enclosure

- Keep away from corrosive gases

- Ensure dust control in CNC workshops

Exposure to moisture or conductive debris can cause short circuits and damage the unit.

Energy Efficiency and Operational Benefits

Using a VFD like the MOLLOM 4KW inverter can significantly reduce energy consumption compared to fixed-speed motor operation.

Efficiency Advantages

- Reduced power usage at partial loads

- Optimized motor speed for specific tasks

- Lower mechanical wear

- Reduced heat generation

These benefits translate into lower operating costs and longer equipment lifespan.

Advantages of the MOLLOM VFD 4KW 5HP

- Supports both single-phase and three-phase input

- High-frequency output up to 3000 Hz

- Compact design with powerful performance

- RS485 MODBUS communication

- User-friendly digital display

- Wide application compatibility

- External braking resistor support

Potential Drawbacks

- Not suitable for humid or wet environments

- Requires proper installation knowledge

- Heavy-load motors may require higher power models

- No built-in waterproof protection

These limitations are common among industrial VFDs and can be managed with proper planning.

Who Should Choose This VFD

The MOLLOM VFD 4KW 5HP is ideal for:

- CNC hobbyists upgrading to industrial-grade control

- Small to medium CNC workshops

- Industrial users requiring high-speed spindle control

- Automation system integrators

- Machine builders seeking flexible input compatibility

Final Verdict

The MOLLOM VFD 4KW 5HP 380V Variable Frequency Drive delivers excellent performance, versatility, and reliability for CNC and industrial motor control applications. Its high-frequency output, robust digital control features, and MODBUS communication make it a strong choice for users who need precise speed regulation and system integration.

When installed and operated correctly, this VFD offers long-term value, energy efficiency, and dependable motor control, making it a worthwhile investment for serious CNC and industrial users.