The ZORZA 60A Dual Channel DC Motor Driver Module is a powerful and versatile motor control solution for robotics, automation systems, and advanced DIY electronics projects. Built to handle heavy current loads and precise speed regulation, this module offers robust performance, efficient heat dissipation, and broad compatibility with common microcontrollers. Below is a detailed exploration of its features, specifications, applications, and practical considerations.

Introduction to High-Performance Motor Drivers

In many engineering and hobbyist projects, controlling DC motors with precision and reliability is crucial. Motor driver modules serve as an interface between low-power control electronics and high-power motors, enabling efficient direction and speed management. The ZORZA 60A Dual Channel DC Motor Driver Module delivers high current handling and effective control, making it an excellent choice for complex systems like robots, automated equipment, and motorized mechanisms where performance matters.

Key Features and Benefits

Dual Channel Control for Independent Motors

The ZORZA motor driver module provides two channels, allowing independent control of two DC motors simultaneously. Each channel can be driven with its own PWM speed signal and direction logic, enabling complex motions such as differential steering in robots or coordinated movement in paired actuators.

Wide Operating Voltage Range (9V-30V)

This module supports a 9V to 30V input voltage range, which makes it compatible with a variety of battery setups and power supplies commonly used in robotics and portable electrical systems. The wide range also provides flexibility for users working with different motor types.

High Current Handling (Up to 60A)

One of the standout features of this expansion board is its ability to handle up to 60 amps per channel, enabling control of larger and more demanding DC motors. This high current capacity is supported by low on-resistance H-Bridge components, which reduce internal power loss and heat buildup.

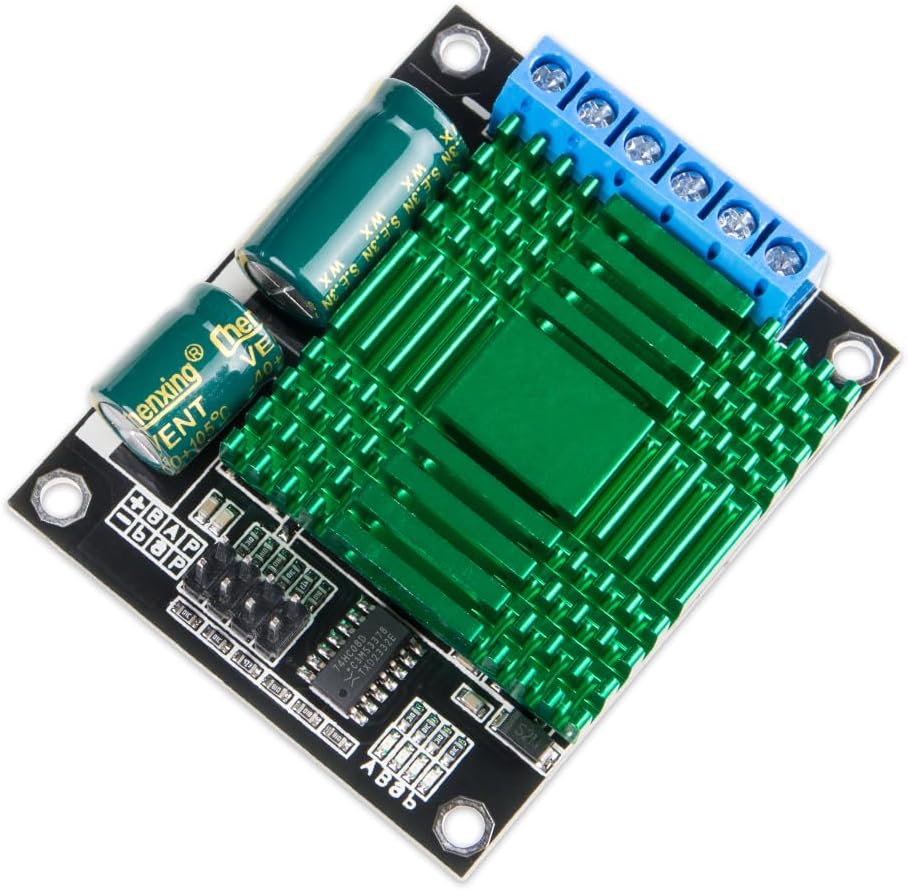

Efficient Heat Dissipation for Reliability

A robust heat sink and effective physical layout help the module maintain stable performance even under sustained high-current operation. Efficient thermal design is essential for preventing overheating and preserving long-term reliability in motor control systems.

High Switching Frequency for Smooth Motor Control

Operating at high PWM switching frequencies (up to around 60 kHz), the module reduces electrical noise and improves motor response. High frequency PWM also helps achieve smoother motor behavior and finer control over speed adjustments.

Simple Control Interface With PWM and Direction Inputs

Control signals for this module are straightforward and compatible with most logic controllers:

- PWM Input: Drive speed by varying the PWM duty cycle.

- Direction Inputs: Logic signals determine forward, reverse, or brake behavior.

- Common Ground: Ensures stable reference between driver and controller.

This familiar control scheme makes the module ideal for use with microcontrollers such as Arduino, ESP32, Raspberry Pi (with proper interfacing), and similar development boards.

Microcontroller Compatibility

The module accepts 3.3V and 5V logic levels, allowing it to interface directly with a wide range of microcontroller platforms without additional level shifting components. This flexibility simplifies prototype development and integration into existing control systems.

Technical Specifications

| Specification | Details |

|---|---|

| Product Name | ZORZA 60A Dual Channel DC Motor Driver Module |

| Channels | Dual channel motor control |

| Operating Voltage Range | 9V – 30V |

| Rated Current (per channel) | Up to 60A |

| Peak Current (approximate) | Higher short bursts possible |

| PWM Switching Frequency | Up to approx. 60 kHz |

| On-Resistance | Very low (approx. 0.003 ohms) |

| Control Signals | PWM, direction logic, brake control |

| Logic Compatibility | 3.3V and 5V |

| Heat Dissipation | Built-in heat sink |

| Ideal Use Cases | Robotics, automation, high-current motor control |

| Typical Weight | About 230 grams |

| Typical Dimensions | Compact board format |

This combination of features and performance capabilities makes the module suited for power-intensive motor tasks where both precision and reliability are required.

Practical Applications

Robotics and Mobile Platforms

For robotics enthusiasts and engineers, the ability to control two motors independently with fine-tuned speed adjustment is essential. This motor driver module enables differential steering and coordinated motor behaviors, which are crucial for mobile robots, robotic arms, and autonomous ground vehicles.

Automation and Mechatronic Systems

In automated systems where motors drive conveyor belts, mechanical actuators, or lifting mechanisms, consistent and accurate motor control is necessary. The high current capacity and PWM speed regulation of this module help maintain performance even in continuous operation.

DIY Electronics and Custom Builds

Hobbyists building custom motorized projects such as motorized carts, remote-controlled vehicles, or automated gadgets can benefit from this module’s robust design and ease of control. Its compatibility with popular microcontrollers and common PWM control schemes makes integration straightforward.

Educational Use in Engineering Labs

Students learning about motor control theory and embedded systems can use this expansion board to gain hands-on experience. By integrating it with hands-on microcontroller projects, learners can explore real-world applications of PWM, H-Bridge control, and high-power electronics.

Installation and Setup Guidelines

Power Supply Considerations

To get started, provide the correct power supply within the recommended 9V to 30V range. Ensure the supply can supply sufficient current for the motors without significant voltage drop, as inadequate power can lead to performance issues.

Connecting Control Signals

Link the PWM output from your microcontroller to the PWM input on the driver module. Use the direction control lines to set motor orientation, and ensure that the ground of your power supply and control board are shared for stable signal referencing.

PWM for Speed Regulation

By adjusting the PWM duty cycle, users can finely control motor speed. Higher duty cycles typically translate into faster motor speeds, while lower duty cycles slow the motor efficiently, without wasting power in resistive elements.

Heat and Airflow Management

Although the module includes heat dissipation features, avoid enclosing it in tightly sealed spaces without airflow. Ensuring adequate ventilation will help maintain efficient thermal performance and extend module life.

Performance and Safety Tips

Managing Current Loads

Even though the module supports up to 60A, always verify that your power source and wiring can handle peak demands. Consider using fuses or current limiting where appropriate to protect components from unexpected surges.

Clean PWM Signals

High-quality PWM signals improve motor stability and reduce noise. Adjust the PWM frequency and duty cycle according to the motor’s characteristics for optimal performance.

Avoiding Electrical Noise Issues

Motor driver systems generate electrical noise, which can interfere with control signals. Using filtering capacitors and maintaining good grounding practices helps mitigate noise and stabilize control signals.

Comparison With Other Motor Driver Options

While the ZORZA 60A Dual Channel DC Motor Driver Module excels in high-current applications, other motor drivers may suit lower power needs. For example, the DFRobot DFR0601 Dual-Channel DC Motor Driver-12A module provides similar dual-channel motor control but with lower current capacity, making it suitable for smaller projects or where energy efficiency is prioritized.

Choosing between high-current and lower-current drivers depends on your motor specifications, application demands, and required control flexibility.

Summary

The ZORZA 60A Dual Channel DC Motor Driver Module 9V-30V PWM Speed Governor Regulator Drive Expansion Board delivers exceptional performance for projects requiring high current handling, precise PWM speed control, and flexible dual motor management. Its wide voltage range, efficient heat dissipation, and compatibility with popular microcontrollers make it a versatile choice for robotics, automation systems, DIY electronics, and educational use.

By integrating robust design and user-friendly control features, this module supports advanced motor control without compromising on reliability or performance.