Introduction

Precision machining, engraving, and light milling demand a spindle motor that is stable, powerful, and reliable. The Walfront Spindle Motor Kit 500W is designed to meet the needs of hobbyists, CNC enthusiasts, and small workshop professionals who require consistent performance and smooth operation. This complete spindle solution integrates a high-speed brushless spindle motor, motor driver, and motor controller, offering a compact yet efficient power system for engraving machines and other light-duty CNC applications.

This article provides a detailed, easy-to-understand breakdown of the Walfront 500W Brushless Spindle Motor Kit. It covers specifications, features, advantages, real-world applications, and technical insights, along with accurate product data tables. The content is structured for clarity, usability, and search engine visibility, while remaining completely free of links, domains, or external references.

Product Overview

The Walfront 500W High Speed Air Cooling Brushless Spindle Motor ER16 is a DC-powered spindle solution operating at 48V with a maximum speed of 12000 RPM. Its brushless design ensures reduced electrical noise, minimal maintenance, and extended service life compared to traditional brushed motors.

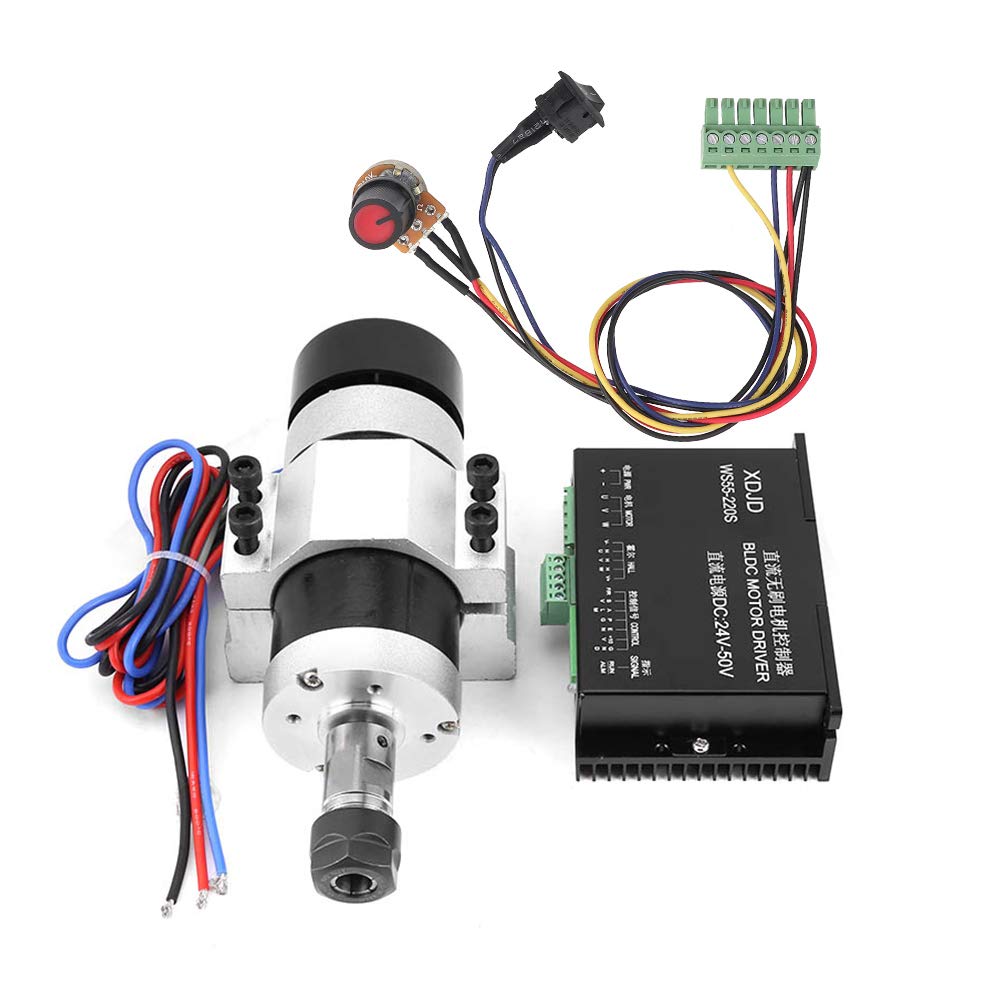

Unlike standalone spindle motors, this kit includes:

- A brushless spindle motor

- A motor driver

- A motor controller

This integration simplifies installation and ensures compatibility between components, making it an excellent choice for both beginners and experienced users.

Key Highlights of the Walfront 500W Spindle Motor Kit

- High-speed performance up to 12000 RPM

- 500W rated power suitable for engraving, drilling, and light milling

- ER16 collet chuck for versatile tool compatibility

- Brushless motor technology for low interference and smooth operation

- Air cooling system for stable temperature control

- Comprehensive driver functions including CW/CCW, speed control, and alarm output

Technical Specifications

Spindle Motor Specifications

| Parameter | Specification |

|---|---|

| Product Name | Walfront Brushless Spindle Motor Kit |

| Rated Power | 500W |

| Input Voltage | DC 48V |

| Maximum Speed | 12000 RPM |

| Motor Type | Brushless DC Motor |

| Cooling Method | Air Cooling |

| Chuck Type | ER16 |

| Overall Motor Length | 19.4 cm / 7.6 in |

| Bearings | High-precision bearing system |

| Noise Level | Low noise operation |

| Maintenance | Low, bearing-based wear |

Motor Driver and Controller Specifications

| Function | Description |

|---|---|

| Hall Sensor Support | Compatible with motors with or without hall sensors |

| Speed Control | Potentiometer speed control supported |

| External Speed Control | External 10V voltage speed control |

| Power Control | Power on/off function |

| Speed Output | Speed signal output supported |

| Alarm Output | Fault and alarm signal output |

| Direction Control | CW/CCW rotation function |

| Application Compatibility | CNC machines, electric tools, fan systems |

Brushless Motor Technology Explained

The brushless spindle motor used in this kit offers several advantages over traditional brushed motors:

Reduced Electrical Interference

Because brushless motors do not generate sparks during operation, they produce significantly less electromagnetic interference. This makes them ideal for CNC environments where electronic components, controllers, and communication systems must operate without disruption.

Improved Efficiency

Brushless motors convert electrical energy into mechanical power more efficiently. This efficiency results in:

- Lower heat generation

- Consistent torque output

- Better speed stability

Longer Service Life

Since there are no brushes to wear out, the primary wear components are the bearings. With proper dust control and occasional cleaning, the motor maintains long-term reliability.

Performance and Speed Stability

Operating at up to 12000 RPM, the Walfront spindle motor provides ample speed for engraving, PCB milling, wood carving, acrylic cutting, and light aluminum work. The ER16 collet system ensures secure tool holding, reducing vibration during high-speed rotation.

The motor controller allows fine-tuned speed adjustments through:

- Manual potentiometer control

- External 10V analog speed input

This flexibility ensures smooth acceleration, stable RPM under load, and consistent machining results.

Noise Reduction and Smooth Operation

One of the standout advantages of the Walfront 500W Brushless Spindle Motor Kit is its low-noise performance. The reduced friction inherent in brushless designs minimizes vibration, which leads to:

- Cleaner surface finishes

- Improved engraving accuracy

- Less mechanical stress on CNC frames

Smooth rotation also protects cutting tools from premature wear, reducing operating costs over time.

Installation and Integration

Compact and CNC-Friendly Design

With an overall length of 19.4 cm, including the fan, ER16 chuck, and motor body, the spindle is compact enough for most desktop and benchtop CNC machines.

Controller Compatibility

The included driver and controller support motors with or without hall sensors, simplifying installation and reducing wiring complexity. Clear function support such as CW/CCW rotation and alarm output improves safety and usability.

Applications of the Walfront 500W Spindle Motor Kit

This spindle motor kit is designed for versatility and can be used across multiple industries and DIY applications.

Primary Applications

| Application Area | Usage |

|---|---|

| CNC Engraving Machines | Wood, plastic, acrylic engraving |

| PCB Milling | Circuit board engraving and drilling |

| Light Metal Processing | Aluminum and soft metal engraving |

| DIY CNC Projects | Hobbyist and educational builds |

| Electric Tools | Custom motor-driven tools |

| Fan Control Systems | Speed-regulated airflow systems |

| Small Appliances | Compact motorized devices |

Advantages Over Brushed Spindle Motors

Comparison Table

| Feature | Brushless Spindle Motor | Brushed Spindle Motor |

|---|---|---|

| Spark Generation | None | Present |

| Electrical Noise | Very Low | High |

| Maintenance | Minimal | Frequent |

| Lifespan | Long | Shorter |

| Efficiency | High | Moderate |

| Operating Noise | Low | Higher |

The Walfront brushless spindle clearly excels in performance, reliability, and operational stability.

Durability and Maintenance

The motor’s durability is primarily defined by its bearing system. Regular maintenance requirements are minimal:

- Periodic dust removal

- Ensuring proper airflow for cooling

- Monitoring bearing noise over time

There are no brushes to replace, making it a cost-effective solution for long-term use.

Safety and Control Features

The motor driver includes built-in safety and monitoring features:

- Alarm output for fault detection

- Controlled startup and shutdown

- Direction control to prevent mechanical stress

These features help protect both the motor and the CNC machine, enhancing operational safety.

Why Choose the Walfront 500W Spindle Motor Kit

The Walfront Spindle Motor Kit 500W stands out as a balanced solution combining power, precision, and reliability. It is particularly well-suited for users who want:

- A complete spindle system with matched components

- Low-noise, low-interference operation

- Easy integration into CNC and DIY projects

- Consistent high-speed performance

Its brushless design ensures that it remains stable under prolonged use while delivering professional-level results.

Conclusion

The Walfront 500W High Speed Air Cooling Brushless Spindle Motor ER16 12000RPM Kit is a dependable choice for engraving machines and light CNC applications. With its integrated motor driver and controller, robust brushless technology, and versatile control features, it delivers smooth, efficient, and long-lasting performance.

Whether used in a home workshop, educational environment, or small production setup, this spindle motor kit offers precision, durability, and ease of use without unnecessary complexity.