Introduction

Precision motion control is the backbone of modern CNC machines, automation systems, and industrial positioning equipment. At the center of this precision lies the stepper motor, a component responsible for converting electrical signals into accurate mechanical movement. The Nema 34 Stepper Motor 6A 8.5Nm (1200 oz-in) 118mm Length is engineered for demanding applications where high torque, reliability, and consistent performance are essential.

This in-depth article explores the HobbyUnlimited Nema 34 stepper motor, covering technical specifications, performance characteristics, build quality, applications, and advantages for CNC routers, mills, and lathes. The content is written in clear, professional language and structured to support strong visibility across major search engines while remaining free of links, domains, or external references.

Product Overview

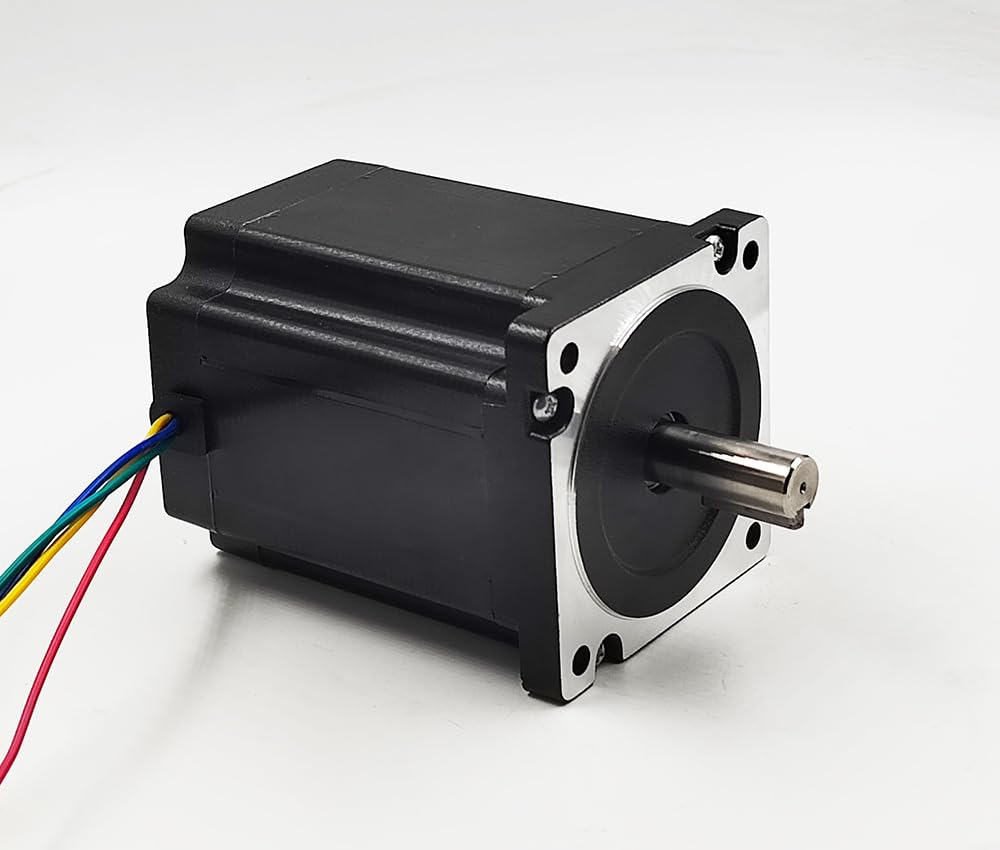

The Nema 34 stepper motor 8.5Nm is a high-torque, heavy-duty motor designed for large CNC machines and industrial automation systems. With a body length of 118mm, a rated current of 6A, and a torque output of 8.5 Newton-meters (1204 oz-in), this motor delivers exceptional holding and dynamic torque for precision motion control.

Manufactured by HobbyUnlimited, this motor is constructed from durable alloy steel and designed to operate reliably under continuous load. Its size, torque rating, and electrical characteristics make it suitable for professional-grade CNC equipment and advanced DIY builds.

Brand and Manufacturer Information

| Attribute | Details |

|---|---|

| Brand Name | HobbyUnlimited |

| Manufacturer | HobbyUnlimited |

| UPC | 636824685644 |

| Customer Rating | 4.6 out of 5 stars |

| Total Reviews | 41 |

| Category Rank | #251 in Electrical Motor Controls |

| Overall Tools Rank | #316,444 in Tools & Home Improvement |

The strong customer rating reflects consistent performance, build quality, and suitability for demanding applications.

Understanding Nema 34 Stepper Motors

What Does Nema 34 Mean

The term Nema 34 refers to the motor’s standardized mounting face size, measuring approximately 3.4 x 3.4 inches. This standardization ensures compatibility with a wide range of CNC frames, motor mounts, and industrial machinery.

Nema 34 motors are typically used when smaller motors, such as Nema 23 or Nema 17, cannot deliver sufficient torque.

Key Technical Specifications

Electrical and Mechanical Specifications

| Specification | Value |

|---|---|

| Motor Type | Stepper Motor |

| Frame Size | Nema 34 |

| Motor Length | 118mm |

| Rated Current | 6 Amps |

| Holding Torque | 8.5 Nm |

| Torque (oz-in) | 1204 oz-in |

| Rated Speed | 100 RPM |

| Voltage Rating | 36V (up to 500V driver compatible) |

| Power Output | 100 Watts |

| Weight | 3.6 kg |

| Material | Alloy Steel |

| Color | Black |

These specifications position the motor as a high-torque solution capable of driving large lead screws, ball screws, and belt-driven systems.

Torque and Performance Analysis

High Holding Torque

With 8.5Nm of holding torque, this Nema 34 stepper motor provides exceptional resistance to external forces when stationary. This is particularly important for:

- Vertical axis motion

- Heavy gantry systems

- Milling operations with cutting resistance

High holding torque ensures the machine maintains position accuracy even under load.

Operational Speed

The motor is rated at 100 RPM, making it ideal for applications where torque and precision are more critical than high rotational speed. When paired with appropriate drivers and motion controllers, it can deliver smooth motion across a broad speed range.

Voltage and Drive Compatibility

The motor is commonly operated at 36V, though it is compatible with stepper drivers capable of handling higher voltages, up to 500V, depending on the driver design. Higher voltage operation improves:

- Acceleration

- High-speed torque retention

- Overall efficiency

Proper driver selection is essential to unlock the full performance potential of this motor.

Build Quality and Materials

Alloy Steel Construction

The motor housing is constructed from high-quality alloy steel, providing:

- Structural rigidity

- Improved heat dissipation

- Resistance to vibration and mechanical stress

This robust construction supports long-term operation in industrial and workshop environments.

Weight and Stability

At 3.6 kilograms, the motor’s mass contributes to stability during operation. The added weight helps dampen vibration, resulting in:

- Smoother motion

- Reduced resonance

- Improved machining accuracy

Precision and Motion Control

Stepper motors are valued for their precise positioning capabilities. This Nema 34 stepper motor 6A excels in:

- Microstepping applications

- Repeatable positioning

- Controlled acceleration and deceleration

These characteristics are essential for CNC milling, engraving, and turning operations.

Applications

CNC Routers

In CNC routers, this motor is ideal for:

- X-axis and Y-axis gantry movement

- Z-axis lift mechanisms

- Large-format cutting tables

Its high torque supports cutting wood, plastics, composites, and soft metals.

CNC Mills

Milling machines require motors that can withstand cutting forces. This motor provides:

- Stable tool positioning

- Reduced step loss under load

- Consistent feed rates

CNC Lathes

In lathe applications, the motor is commonly used for:

- Carriage movement

- Cross-slide control

- Automated tool positioning

High torque ensures smooth, controlled motion during turning operations.

Industrial Automation

Beyond CNC machines, this motor is suitable for:

- Linear actuators

- Conveyor positioning systems

- Robotic axes

- Automated assembly equipment

Thermal Performance

Stepper motors generate heat during operation, particularly under high load. The alloy steel body and internal design support efficient heat dissipation, allowing:

- Continuous operation

- Stable electrical performance

- Reduced risk of overheating when properly driven

Adequate ventilation and correct current settings further enhance thermal stability.

Ease of Integration

Standardized Mounting

The Nema 34 frame size ensures compatibility with:

- Standard motor mounts

- CNC kits

- Retrofit projects

This simplifies installation and replacement.

Wiring and Control

With a 6A current rating, the motor integrates seamlessly with most high-power stepper drivers. Proper wiring and shielding help maintain signal integrity and smooth operation.

Reliability and Service Life

The HobbyUnlimited Nema 34 stepper motor is designed for long service life, thanks to:

- Precision bearings

- Robust internal components

- Consistent manufacturing quality

Routine maintenance is minimal, typically limited to keeping the motor clean and ensuring secure mounting.

User Feedback and Market Position

With a 4.6 out of 5 stars customer rating, users consistently highlight:

- Strong torque output

- Reliable operation

- Solid construction

- Good value for high-power applications

Its ranking within the electrical motor controls category reflects its popularity among CNC builders and automation professionals.

Comparison with Smaller Stepper Motors

| Feature | Nema 23 | Nema 34 |

|---|---|---|

| Typical Torque | 1–3 Nm | 6–12 Nm |

| Weight | Light | Heavy |

| Application Size | Small CNC | Large CNC |

| Load Capacity | Moderate | High |

| Precision | High | High |

The Nema 34 stepper motor 8.5Nm is clearly suited for larger, heavier systems where torque is a priority.

Why Choose the HobbyUnlimited Nema 34 Stepper Motor

This motor is an excellent choice for users who require:

- High torque for heavy loads

- Reliable performance under continuous operation

- Compatibility with industrial CNC systems

- Durable construction with professional-grade materials

Its specifications make it well-suited for serious CNC enthusiasts and industrial users alike.

Conclusion

The Nema 34 Stepper Motor 6A 8.5Nm 118mm Length by HobbyUnlimited is a powerful, reliable solution for CNC routers, mills, lathes, and automation systems. With its high torque output, solid alloy steel construction, and proven user satisfaction, it delivers consistent performance in demanding environments.

For applications where precision, stability, and torque are non-negotiable, this stepper motor stands as a dependable choice capable of supporting advanced motion control systems and large-scale CNC machinery.