The precision and reliability of a CNC machine, 3D printer, laser engraver, or automated motion system depend heavily on the quality of its motor drivers. A stepper motor driver is not just a power amplifier; it is the control heart that determines smoothness, accuracy, noise level, and thermal performance. The DEVMO DM542 M542 Stepper Motor Driver, compatible with the well-known Leadshine DM542 design, is a highly regarded 2-phase digital micro-stepping driver engineered for demanding motion-control applications.

This in-depth review explores the DEVMO DM542 stepper motor driver in detail, explaining how it works, what makes it different from traditional drivers, and why it has become a popular choice for CNC builders, automation professionals, and advanced hobbyists. The article is written to be easy to understand while still delivering professional-grade technical clarity.

Introduction to Digital Stepper Motor Drivers

Stepper motors are widely used in precision positioning systems because they move in discrete steps, allowing accurate control of position and speed. However, the motor itself is only part of the equation. The driver determines:

- How smoothly the motor rotates

- How much torque is available

- How much noise and vibration is generated

- How efficiently electrical power is used

Traditional analog stepper drivers rely on basic current chopping methods that often produce audible noise, excessive heat, and mechanical vibration. Modern digital stepper motor drivers, such as the DEVMO DM542, use advanced DSP (Digital Signal Processing) algorithms to deliver smoother motion, quieter operation, and improved thermal efficiency.

Product Overview: DEVMO DM542 M542 Stepper Motor Driver

The DEVMO DM542 M542 is a 2-phase CNC micro-stepping digital stepper motor driver controller designed for medium-power stepper motors. It supports a wide current range and input voltage, making it suitable for many CNC and automation applications.

This driver is based on the proven Leadshine DM542 architecture, known for its stability, reliability, and performance. It is commonly used in:

- CNC routers

- CNC milling machines

- Laser engraving machines

- Plasma cutters

- Automated linear motion systems

- Industrial and laboratory equipment

The driver supports micro-stepping, allowing motors to move in smaller increments than full steps, resulting in smoother motion and higher positional resolution.

Key Features of the DEVMO DM542 Digital Stepper Motor Driver

Advanced DSP Control Algorithm

One of the most important features of the DEVMO DM542 stepper motor driver is its use of an advanced DSP control algorithm. DSP technology allows the driver to precisely regulate motor current in real time, optimizing torque output while minimizing vibration and noise.

Benefits of DSP control include:

- Exceptionally smooth motor movement

- Reduced resonance and mid-range instability

- Lower audible noise compared to analog drivers

- Improved efficiency and reduced heat generation

This makes the DM542 an excellent upgrade from older, traditional stepper drivers.

Wide Output Current Range

The DM542 CNC driver offers a flexible output current range suitable for many popular stepper motors.

- Output peak current: 1.0A to 4.2A

- RMS current: up to 3.0A

This wide range allows compatibility with NEMA 17, NEMA 23, and some smaller NEMA 34 stepper motors, depending on their rated current.

Adjustable current settings help users match the driver precisely to the motor, improving torque while preventing overheating.

Broad Input Voltage Support

The DEVMO DM542 supports a 20–50V DC input voltage range, with 36V DC being the typical recommended operating voltage.

Higher voltage operation provides:

- Better high-speed performance

- Faster current rise time

- Improved torque at higher RPM

This makes the driver suitable for applications requiring both precision and speed.

High Pulse Input Frequency

With a pulse input frequency of up to 200kHz, the DM542 stepper driver can handle high-resolution motion control systems without missing steps.

This feature is especially important for:

- CNC machines using high micro-stepping settings

- High-speed motion control applications

- Controllers with fast pulse output

The high pulse rate ensures smooth and accurate response even at demanding speeds.

Micro-Stepping Capability

Micro-stepping divides each full motor step into smaller steps, dramatically improving motion smoothness and resolution. The DEVMO DM542 supports a wide range of micro-stepping settings, allowing users to fine-tune performance for their specific application.

Advantages of micro-stepping include:

- Reduced vibration

- Lower noise

- Improved surface finish in CNC machining

- Increased positioning accuracy

This makes the DM542 particularly popular in CNC and engraving applications.

Low Noise and Low Heat Generation

Compared with traditional stepper drivers, the DEVMO DM542 digital stepper motor driver produces significantly less noise and thermal output.

Lower noise improves working comfort and reduces mechanical wear, while lower heat generation:

- Extends driver lifespan

- Improves system reliability

- Reduces the need for large heat sinks or active cooling

These characteristics make the driver suitable for long-duration operation in enclosed control boxes.

Technical Specifications Table

The following table summarizes the core specifications of the DEVMO DM542 M542 stepper motor driver:

| Specification | Details |

|---|---|

| Product Type | Digital micro-stepping stepper motor driver |

| Model | DM542 / M542 |

| Motor Type | 2-phase stepper motor |

| Output Peak Current | 1.0 – 4.2A |

| RMS Current | Up to 3.0A |

| Input Voltage | 20 – 50V DC |

| Typical Voltage | 36V DC |

| Logic Signal Current | 7 – 16mA (typical 10mA) |

| Pulse Input Frequency | 0 – 200kHz |

| Control Method | DSP digital control |

| Micro-Stepping | Supported |

| Noise Level | Low |

| Thermal Output | Reduced |

| Package Contents | 1 × DM542 stepper motor driver |

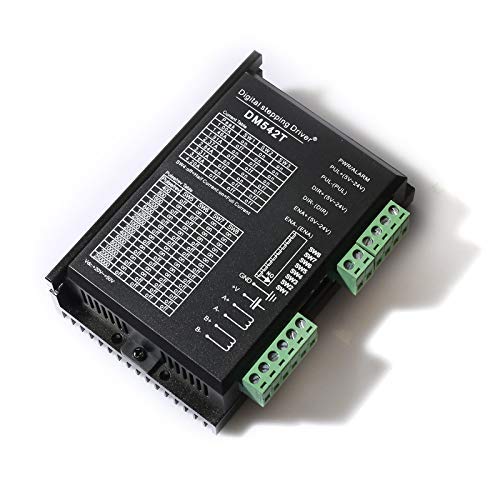

Build Quality and Design

The DEVMO DM542 CNC driver features a robust industrial design intended for long-term reliability. The metal housing improves heat dissipation and protects internal electronics from electromagnetic interference.

Key design highlights include:

- Solid terminal blocks for secure wiring

- Clear labeling for signal and power connections

- Compact form factor suitable for control cabinets

- Durable construction for industrial environments

This design ensures stable performance even in electrically noisy CNC systems.

Installation and Wiring Overview

Installing the DM542 stepper motor driver is straightforward for users familiar with CNC electronics.

Typical connections include:

- DC power supply (20–50V DC)

- Step and direction signals from the controller

- Enable signal (optional)

- Stepper motor phase wiring

Proper wiring and correct current setting are essential to ensure safe and efficient operation. The adjustable current settings allow users to match the driver precisely to their motor specifications.

Performance in CNC Applications

Smooth Motion and Precision

In CNC machines, motion quality directly affects surface finish and dimensional accuracy. The DEVMO DM542 excels in this area, delivering smooth acceleration and deceleration with minimal vibration.

This is particularly noticeable in:

- CNC routers performing contour cutting

- Laser engravers producing fine details

- Milling machines requiring stable tool paths

The DSP algorithm actively minimizes resonance, improving overall motion stability.

High-Speed Capability

Thanks to its high pulse input frequency and optimized current control, the DM542 CNC stepper driver maintains torque at higher speeds compared to basic drivers.

This allows machines to:

- Move faster without losing steps

- Increase productivity

- Maintain accuracy at higher feed rates

Thermal Stability

Thermal performance is critical in CNC systems that run for extended periods. The DEVMO DM542 remains relatively cool under normal operating conditions, reducing the risk of thermal shutdown or component degradation.

Applications and Use Cases

The DEVMO DM542 stepper motor driver is suitable for a wide range of applications, including:

- CNC routers and milling machines

- Laser cutting and engraving systems

- Plasma cutting tables

- Automated positioning systems

- Pick-and-place machines

- Industrial automation equipment

Its flexibility makes it a popular choice for both professional and advanced DIY projects.

Advantages of the DEVMO DM542

- Advanced DSP digital control

- Smooth, quiet motor operation

- Wide current and voltage range

- High pulse frequency support

- Reliable thermal performance

- Compatible with many 2-phase stepper motors

Considerations Before Purchase

While the DM542 stepper driver offers excellent performance, users should consider:

- Proper power supply selection

- Correct current setting for the motor

- Adequate ventilation in control enclosures

Ensuring these factors are addressed will maximize performance and longevity.

Comparison with Traditional Stepper Drivers

Compared to traditional analog stepper drivers, the DEVMO DM542 offers:

- Significantly lower noise

- Reduced vibration

- Better torque utilization

- Improved efficiency

- Greater reliability

These advantages make digital drivers the preferred choice for modern CNC systems.

Long-Term Reliability and Value

The combination of digital control, solid construction, and efficient thermal management contributes to long-term reliability. For CNC builders and professionals, the DEVMO DM542 represents strong value by reducing maintenance needs and improving machine performance.

Final Verdict

The DEVMO DM542 M542 Stepper Motor Driver is a powerful, reliable, and efficient digital micro-stepping CNC driver suitable for a wide range of motion control applications. Its advanced DSP algorithm delivers smoother motion, lower noise, and reduced heat compared to traditional drivers.

For CNC enthusiasts, automation engineers, and machine builders seeking a dependable 2-phase stepper motor driver, the DM542 stands out as a proven and capable solution that balances performance, stability, and ease of use.