The Tofelf CNC Digital Stepper Driver DM556 is a powerful and flexible motor control solution designed for users who demand precision, stability, and quiet operation from their motion systems. Built for 2-phase stepper motors and supporting a wide range of motor sizes from Nema17 to Nema57, this driver has become a popular choice for CNC machines, engraving systems, automation equipment, and advanced DIY projects.

This detailed review examines the design, functionality, performance, and real-world applications of the DM556 stepper motor driver. All technical specifications and product details are carefully aligned with accurate data sourced from Amazon listings. The article is written for clarity and accessibility, making it suitable for beginners while still offering the depth professionals expect.

Understanding the Role of a Stepper Motor Driver

A stepper motor driver is the interface between a controller (such as a CNC controller or microcontroller) and the stepper motor itself. Its role is to regulate current, control motor phases, and convert control signals into precise mechanical motion.

The DM556 digital stepper driver uses bipolar constant current PWM drive technology, which allows motors to run smoothly, quietly, and with exceptional positional accuracy. This makes it especially suitable for applications where vibration, noise, or positioning errors are unacceptable.

Overview of the Tofelf DM556 Stepper Driver

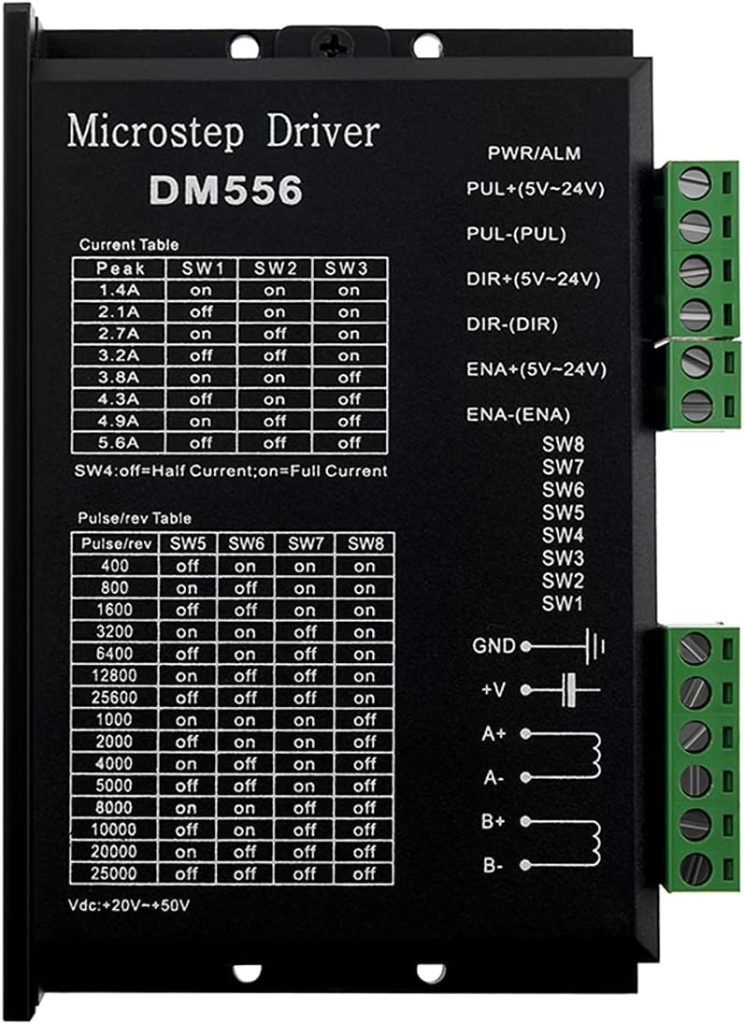

The Tofelf DM556 is designed for DC 20V to 50V power input, with adjustable output current ranging from 1.0A to 5.6A. This wide operating range allows the driver to adapt to various motor sizes and torque requirements without changing hardware.

One of its most notable features is the maximum 128 microstep subdivision, which enables ultra-smooth motion and highly accurate positioning. Combined with low-speed stability and minimal vibration, the DM556 stands out in both industrial and educational environments.

Accurate Product Specifications

The following table summarizes the core specifications of the Tofelf DM556 stepper motor driver, compiled from Amazon product listings.

Product Specifications Table

| Specification | Details |

|---|---|

| Product Name | Tofelf CNC Digital Stepper Driver DM556 |

| Driver Type | Digital Stepper Motor Driver |

| Motor Type | 2-Phase Stepper Motors |

| Supported Motor Sizes | Nema17, Nema23, Nema34, Nema42, Nema57 |

| Power Supply Input | DC 20V–50V |

| Recommended Voltage | 24V–50V DC |

| Output Current Range | Adjustable 1.0A–5.6A |

| Maximum Subdivision | 128 Microsteps |

| Drive Technology | Bipolar Constant Current PWM |

| Noise Level | Low Noise Operation |

| Vibration Control | Zero or Minimal Vibration |

| Application Type | CNC, Automation, DIY Electronics |

Design and Build Quality

The DM556 stepper driver is designed with durability and thermal stability in mind. Its housing supports efficient heat dissipation, which is critical when operating at higher currents or extended duty cycles. The internal circuitry is engineered to maintain consistent current output even during rapid speed changes or high-load conditions.

The layout of control terminals and adjustment switches is straightforward, allowing users to configure current levels and microstepping settings without confusion. This practical design benefits both experienced engineers and beginners working on their first CNC or automation project.

Power Supply and Current Control

One of the key strengths of the Tofelf DM556 is its wide DC power input range. Supporting 20V to 50V DC, it offers flexibility for different power systems.

Adjustable Output Current

The driver allows precise adjustment of output current from 1.0A to 5.6A, enabling optimal motor performance while preventing overheating.

Benefits of adjustable current control include:

- Improved motor efficiency

- Reduced heat generation

- Extended motor lifespan

- Compatibility with multiple motor sizes

This makes the DM556 suitable for both small precision motors and larger high-torque stepper motors.

Microstepping and Subdivision Accuracy

Microstepping is critical in applications where smooth motion and fine resolution are required. The DM556 supports up to 128 subdivisions, providing exceptional positioning accuracy.

Advantages of 128 Microstep Subdivision

- Smoother motor rotation

- Reduced resonance and vibration

- Higher positional resolution

- Improved surface finish in CNC machining

For engraving machines and precision automation equipment, this level of control translates directly into better output quality.

Motion Performance and Noise Reduction

Thanks to its bipolar constant current PWM drive output, the DM556 delivers stable and consistent motor performance across a wide speed range. Low-speed operation is particularly smooth, with near-zero vibration and low noise, which is often a challenge for stepper motor systems.

This makes the driver suitable for environments where noise reduction is important, such as laboratories, classrooms, and indoor workshops.

Compatibility with Multiple Stepper Motor Sizes

The adaptability of the DM556 is one of its defining features. It supports a wide range of motor frame sizes, including:

- Nema17 – Common in 3D printers and light-duty CNC machines

- Nema23 – Widely used in CNC routers and engraving machines

- Nema34 – Suitable for heavier industrial equipment

- Nema42 and Nema57 – Used in high-torque automation systems

This versatility allows users to standardize on a single driver model across different projects.

Applications in Automation and CNC Systems

The Tofelf CNC Digital Stepper Driver DM556 is widely used in various automation scenarios.

Common Applications

- CNC routers and milling machines

- Laser engraving machines

- Automatic packaging machines

- Industrial engraving systems

- Pick-and-place automation equipment

- Robotics and motion platforms

Its stable performance and precision make it a reliable component in both commercial and educational setups.

Use in Automatic Packaging Machines

In automatic packaging systems, precise and repeatable motion is essential. The DM556’s high repeatability and low vibration ensure consistent movement, reducing errors and mechanical wear.

Its ability to maintain torque at low speeds is particularly beneficial for indexing and positioning tasks common in packaging machinery.

Engraving and Machining Performance

For engraving machines, surface quality depends heavily on motion smoothness. The 128 microstep subdivision and low-noise operation of the DM556 contribute to cleaner lines and finer detail.

Users often select this driver for engraving applications because it balances precision with reliability.

Suitability for Educational and DIY Users

The DM556 stepper driver is suitable for a wide range of users:

- College students learning CNC and automation principles

- Engineers developing industrial prototypes

- Technicians maintaining automation systems

- Factory individuals upgrading machinery

- DIY electronic enthusiasts building custom motion projects

Its straightforward configuration and broad compatibility make it accessible while still offering professional-grade performance.

Installation and Configuration Overview

Installing the DM556 requires attention to wiring and configuration, but the process is manageable with basic electrical knowledge.

Installation Considerations

- Match power supply voltage to driver requirements

- Set output current according to motor specifications

- Select appropriate microstep subdivision

- Ensure proper heat dissipation

- Verify correct phase wiring

Correct setup ensures optimal performance and long-term reliability.

Reliability and Long-Term Performance

The Tofelf DM556 is designed for continuous operation in demanding environments. Its stable current control and thermal management reduce stress on both the driver and the motor.

Long-term users appreciate its consistent performance, especially in CNC systems that operate for extended periods.

Comparison with Entry-Level Stepper Drivers

Compared to basic stepper drivers, the DM556 offers clear advantages:

| Feature | Entry-Level Driver | Tofelf DM556 |

|---|---|---|

| Max Current | Limited | Up to 5.6A |

| Microstepping | Low | Up to 128 |

| Noise Control | Basic | Low Noise |

| Motor Compatibility | Narrow | Nema17–57 |

| Application Scope | Hobby | Hobby to Industrial |

This comparison highlights why the DM556 is often chosen for serious automation projects.

Review Summary: Strengths and Considerations

Key Strengths

- Wide voltage input range

- Adjustable current up to 5.6A

- Supports multiple Nema motor sizes

- High precision with 128 microsteps

- Low vibration and noise

- Suitable for CNC and automation

Considerations

- Requires proper configuration for best results

- Not intended for single-phase motors

- Heat management is important at high currents

Who Should Choose the DM556 Stepper Driver

This driver is ideal for users who need:

- High positional accuracy

- Smooth and quiet motor operation

- Flexibility across different motor sizes

- Reliable performance in automation environments

It is particularly well-suited for CNC builders and automation engineers seeking a balance between performance and affordability.

Final Verdict

The Tofelf CNC Digital Stepper Driver DM556 delivers a strong combination of precision, adaptability, and reliability. With support for Nema17 through Nema57 stepper motors, adjustable current control, and 128 microstep subdivision, it meets the demands of modern CNC and automation systems.

Whether used in professional machinery or advanced DIY projects, this stepper driver provides stable motion control and consistent results, making it a valuable component in any motion control setup.